WOTAN

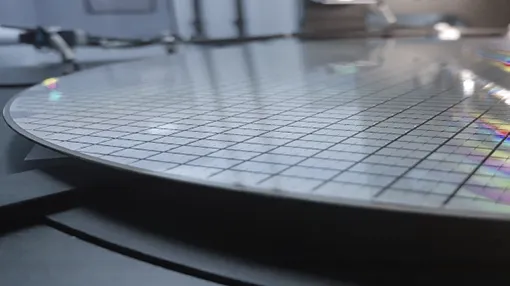

Automated Optical Inspection (AOI) solutionsWOTAN: a unique AOI solution with Full-Color Optics and Simultaneous-Dual-Sided Inspection capabilities.

WOTAN is a high speed AOI tool, with fully automatic-recipe-setup, meaning no parameter selection is needed by human users.

Uniquely in the market, WOTAN uses full colour optics enabling better Sensitivity & Classification (versus the typical Black & White optics of other AOI systems).

The WOTAN has simultaneous front and back side inspection and is able to automatically detect macro sized defects as well as wafer-to-wafer differences.

A key application is high throughput process monitoring and tool control, with easy-to-read instant result display options that enable short defect elimination cycle-times.

WOTAN is available as a stand-alone tool, or in combination with an Edge inspection module.

Exploring WOTAN Key Use-Cases

- High Device Mix fabs, with large numbers’s of recipes, who want to minimize human / operator involvement

- Litho Defocus & Field-Tilt issues

- Colour Defect Detection & Binning

- Wafer Level Defect Signature Detection

- Backside Roughness Monitoring

- Backside Defectivity Monitoring

- Automated Scribe Line Masking